Introduction

In today’s rapidly evolving electronics industry, the demand for high-performance, compact and reliable circuit boards has led to the development and widespread adoption of HDI rigid-flex PCB (High Density Interconnect Rigid-Flex Printed Circuit Board) technology. This article explores the technical aspects, applications and advantages of HDI rigid-flex PCBs and illustrates their importance in electronics manufacturing.

Definition of HDI rigid-flex PCB

HDI rigid-flex PCB represents a major advancement in printed circuit board technology. It combines high-density interconnect capabilities with the flexibility of rigid-flex boards to provide compact, lightweight and reliable solutions for modern electronic designs. The importance of HDI rigid-flex PCB in electronics manufacturing cannot be overstated due to its ability to create complex and dense circuits and improve signal integrity and reliability, making it an important component in a variety of electronic devices.

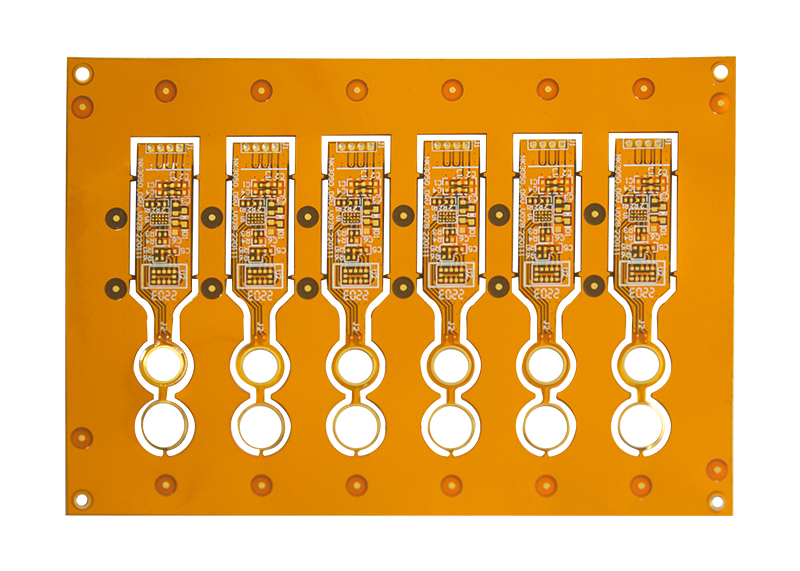

What is HDI rigid flexible pcb board?

A. HDI (High Density Interconnect) Technology Description:

HDI technology involves the use of microvias, fine line circuits, and high-density interconnects to achieve higher circuit density in a smaller footprint. This enables the creation of complex, high-performance electronic devices such as smartphones, wearables, and medical instruments with reduced size and weight.

B. Overview of Rigid-Flex PCB:

Rigid-flex PCB combines rigid and flexible board substrates, allowing three-dimensional circuit configuration and improved reliability compared to traditional rigid or flexible PCBs. Seamless integration of rigid and flexible sections on a single board provides design flexibility and minimizes the need for connectors and cables, helping to save overall space and weight.

C. Advantages of using HDI rigid-flex printed circuit boards:

HDI rigid-flex PCB offers a variety of advantages, including enhanced electrical performance, reduced assembly and interconnection points, improved thermal management, and increased design flexibility. These advantages make them ideal for applications requiring compact, lightweight and reliable circuit solutions.

D. Applications and industries that benefit from HDI rigid-flex circuit board:

The versatility of HDI rigid-flex PCB technology makes it suitable for a wide range of applications and industries, including aerospace, automotive, medical devices, telecommunications and consumer electronics. These industries benefit from the compact size, durability and high performance of HDI rigid-flex PCBs in their products, driving innovation and efficiency in electronics manufacturing.

The main features of HDI rigid-flex board

A. Ultra-thin and lightweight design:

The ultra-thin and lightweight characteristics of HDI rigid-flex board make it very suitable for portable electronic devices and applications with strict size and weight requirements. Its compact form factor enables the development of stylish, space-saving products without compromising performance.

B. Improved reliability and durability: HDI rigid-flex PCB is known for its rugged structure, which enhances reliability and durability in harsh environments. The combination of rigid and flexible substrates provides mechanical stability and resistance to bending-related stresses, making it suitable for applications with repeated bending or vibration.

C. Improve signal integrity and electrical performance:

The advanced interconnect technology used in HDI rigid-flex boards ensures high signal integrity and electrical performance, reducing signal loss, electromagnetic interference and crosstalk. This improves overall system performance and reliability, which is critical for high-speed digital and analog applications.

D. Flexibility and ability to fit into tight spaces:

The inherent flexibility of rigid-flex PCBs allows them to conform to non-linear shapes and fit into limited spaces within electronic devices, thereby maximizing design possibilities and enabling innovative product architectures. This flexibility is particularly beneficial for miniaturized and portable electronics where space utilization is critical.

Things to Consider When Designing and Manufacturing HDI Rigid-Flex PCBs

A. Design Guidelines for HDI Technology:

The design of HDI rigid-flex PCBs requires attention to specific guidelines related to layer stacking, microvia design, impedance control, and signal isolation. Understanding and adhering to these design considerations is critical to ensuring the signal integrity, manufacturability, and reliability of the final product.

B. Best Practices for Manufacturing Rigid-Flex PCBs: The manufacturing process of rigid-flex PCBs involves unique challenges related to material selection, lamination, drilling, and assembly. Following manufacturing best practices, including proper material handling, controlled impedance manufacturing and flex circuit assembly techniques, is critical to achieving high quality and reliable HDI rigid-flex PCBs.

C. Quality Control and Testing Procedures:

Comprehensive quality control measures and testing procedures throughout the manufacturing process are critical to verify the performance, reliability and durability of HDI rigid-flex PCBs. Quality control protocols should include material inspection, process monitoring, electrical testing and reliability assessment to ensure compliance with industry standards and customer requirements.

Common challenges and how to overcome them

A. Design reliability and signal integrity:

Ensuring design reliability and signal integrity of HDI rigid-flex PCBs requires careful attention to layout, material selection, and signal routing. By leveraging advanced design tools, simulation techniques, and comprehensive design reviews, potential issues related to signal integrity and reliability can be identified and mitigated early in the design phase.

B. Minimize material and manufacturing costs:

Utilizing cost-effective materials, efficient manufacturing processes, and optimized designs are critical to minimizing the material and manufacturing costs associated with HDI rigid-flex PCB production. Working with experienced suppliers and manufacturers can facilitate cost-saving opportunities without compromising quality and performance.

C. Meeting the unique requirements of HDI rigid-flex PCBs:

The unique requirements of HDI rigid-flex PCBs require an in-depth understanding of the technologies, materials and manufacturing processes involved. Meeting these requirements requires close collaboration between design engineers, materials suppliers and manufacturing partners to develop customized solutions that meet the specific needs of each application.

HDI Rigid Flex PCB Fabrication Process

Conclusion

The advantages and applications of HDI rigid-flex PCBs have made them an indispensable component in electronics manufacturing, enabling the development of cutting-edge products with enhanced functionality and miniaturized form factors. With the continuous advancement of technology, HDI technology has broad prospects in the electronics industry, and continuous innovation is driving further improvements in performance, reliability, and cost-effectiveness. For more information about HDI rigid-flex PCBs, industry professionals, engineers and designers can explore a variety of professional resources, publications and industry events dedicated to this evolving technology.

In summary, HDI rigid-flex PCB technology represents an important development in electronics manufacturing, providing unparalleled design flexibility, performance and reliability. With its wide application in various industries and continuous technological advancement, HDI rigid-flex PCB is expected to play a key role in shaping the future of electronic devices and systems.

Post time: Jan-16-2024

Back