Introduce:

Welcome to another informative blog post from Capel, a prominent player in the circuit board industry for the past 15 years. In this article, we will discuss the feasibility and advantages of using surface mount components in PCB board prototyping projects. As a leading manufacturer, we aim to provide rapid PCB prototyping production, circuit board prototype assembly services and a comprehensive one-stop solution for all your circuit board needs.

Part 1: Understanding the Basics of Surface Mount Components

Surface mount components, also known as SMD (surface mount device) components, are becoming increasingly popular in the electronics industry due to their smaller size, automated assembly and lower cost. Unlike traditional through-hole components, SMD components are mounted directly on the PCB surface, reducing space requirements and enabling miniaturization of electronic devices.

Part 2: Advantages of using surface mount components in PCB board prototyping

2.1 Efficient use of space: The compact size of SMD components enables higher component density, allowing designers to create smaller, lighter circuits without compromising functionality.

2.2 Improved electrical performance: Surface mount technology provides shorter current paths, reducing parasitic inductance, resistance and capacitance. As a result, this improves signal integrity, reduces noise, and enhances overall electrical performance.

2.3 Cost-Effectiveness: SMD components can be easily automated during assembly, thereby reducing production time and costs. Additionally, their smaller size reduces shipping and storage costs.

2.4 Enhanced mechanical strength: Because surface mount components are directly adhered to the PCB surface, they provide greater mechanical stability, making the circuit more resistant to environmental stress and vibration.

Section 3: Considerations and Challenges of Introducing Surface Mount Components into PCB Board Prototyping

3.1 Design Guidelines: When incorporating SMD components, designers must adhere to specific guidelines to ensure proper layout, component alignment, and soldering integrity during assembly.

3.2 Soldering technology: Surface mount components usually use reflow soldering technology, which requires specialized equipment and a controlled temperature profile. Extra care must be taken to avoid overheating or incomplete solder joints.

3.3 Component Availability and Selection: While surface mount components are widely available, it is crucial to consider factors such as availability, lead time, and compatibility when selecting components for PCB board prototyping.

Part 4: How Capel can help you integrate surface mount components

At Capel, we understand the importance of staying up to date on the latest technological advancements. With our extensive experience in PCB board prototyping and assembly, we offer comprehensive support and custom solutions to integrate surface mount components into your designs.

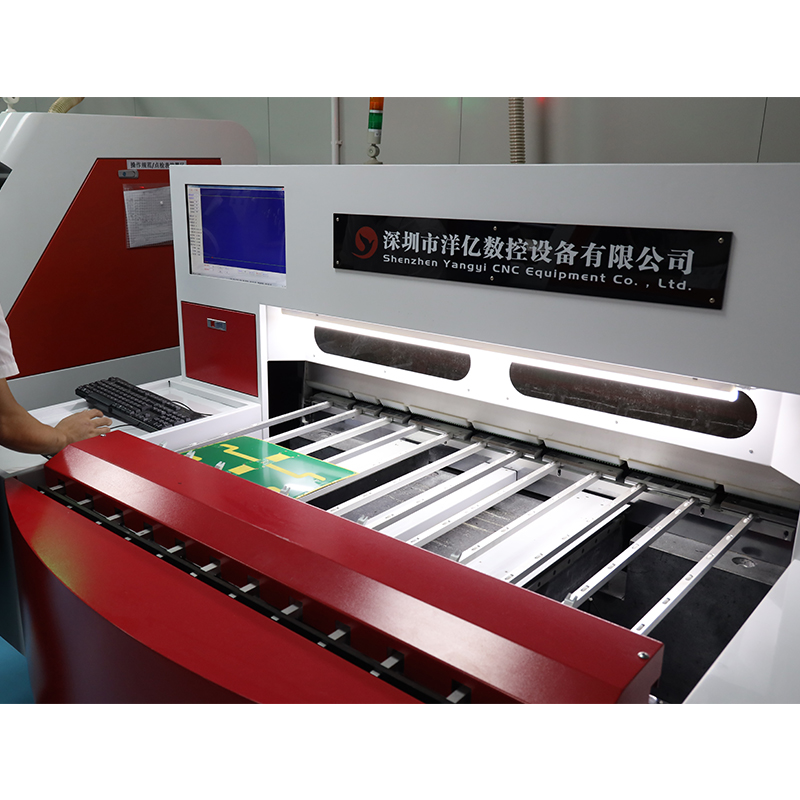

4.1 Advanced Manufacturing Facility: Capel has a state-of-the-art manufacturing facility equipped with cutting-edge machinery that enables us to handle complex surface mount assembly processes with precision and efficiency.

4.2 Component Procurement: We have established strategic partnerships with reputable component suppliers to ensure that we provide high-quality surface mount components for your PCB board prototyping project.

4.3 Skilled Team: Capel has a team of highly skilled technicians and engineers who have the expertise to address the challenges associated with integrating surface mount components. Rest assured that your project will be handled with the utmost care and professionalism.

In conclusion:

Using surface mount components in PCB board prototyping can bring many advantages, such as greater mechanical stability, improved electrical performance, increased efficiency and cost-effectiveness. By partnering with Capel, a leading manufacturer in the circuit board industry, you can leverage our expertise, advanced manufacturing facilities and comprehensive turnkey solutions to simplify your journey to successful surface mount integration. Contact us today to learn how we can help you with your PCB board prototyping efforts.

Post time: Oct-16-2023

Back